Stories Jansen Poultry Equipment

Jansen Poultry Equipment

- Barneveld, Netherlands

- Dynamics NAV

- Manufacturing

Poultry Equipment Leader Streamlines the Creation of Highly Complex, Sophisticated and Tailored Quotes

Benefits

- Built to handle thousands of configurations.

- Smart, guided selling functions.

- Multi-language support.

- Error-free quotes tailored to customers' specific needs.

- Seamless integration with Dynamics NAV.

“Quotes and orders can be created in the customer’s preferred language. Country-specific regulations are automatically associated when creating quotes and orders.”

Jansen Poultry Equipment was founded in 1986 by A. H. Jansen to develop and produce the first automatic egg laying nests. With his knowledge of technology and poultry, Jansen succeeded in developing the most sought-after laying nest. Today the company offers a wide range of poultry systems and has grown to become a flourishing international company with its headquarters located in the Netherlands.

Challenge

At first, Jansen Poultry was a weekend project that A. H. Jansen and his father fit into the hard work of running a farm. Their first project was a prototype for an automated layout litter for chickens, which soon was adopted by many other suppliers of eggs and poultry.

Growth moved as quickly as that initial success – within a few years, Jansen was a fully accredited international presence focused on selling and launching multiple poultry equipment products. In 1994, the company began automating back-office administration and soon included production process automation and CAD into the fold of innovation. Jansen brought everything together in 2001 when they chose Navision (now Microsoft Dynamics NAV) for their ERP system and CPQ as their product configurator solution.

Solution

Jansen was looking at more than 20,000 product configurations per year. All machinery is custom-made and built to recognize customer-specific dimensions of stables and halls. One configuration can contain thousands of specifications that need to surface as quotes that are reasonably streamlined and easy to understand. Salespeople are limited in their choices. To ensure accuracy, CPQ advises them to choose from standard options.

But CPQ also adds smart functionality that allows sales to quote customized options using select text fields, cost indications, and other helpful aids. The rules engine can hold all data and thousands of configurations. Sales and customers see the right selections and are prompted to make the right choices through guided selling. Results are accurate and just as important. They can be pushed to the ERP system and converted to orders with a few clicks, including BOMs, items, and routings – everything needed to get orders to production and delivery as quickly as possible. Jansen faces many challenges in a very competitive marketplace, and with CPQ, they’re better able to keep pace with demand.

No two companies in the poultry industry work with the same dimensions, and they’ve got to balance efficient use of space and a healthy, compliant environment for animals. CPQ can take all data and pull together a perfect recommendation for equipment and much more. Take cages as an example. CPQ efficiently takes into account premise dimensions, animal target weight, specific materials that the customer wants to use, and incredibly complex calculations for equipment parts – CPQ can cover the most exacting details about, for instance, tubing curves and thickness and their relationship to both the equipment itself and where and how it will be located and positioned. The result gives Jansen an optimal recommendation because it’s based on a full view of information that updates real-time with any changes. The tool can go even further and recommend the optimal layout and number of cages for the facility – all tailored to the specific customer.

Along with their reputation for producing just what the customer wants, Jansen Poultry can work quickly with customers who speak different languages and have additional regulatory requirements. The company uses the configurator in 6 other languages: “Quotes and orders can be created in the customer’s preferred language, and at the same time, a Dutch employee can work with the order in Dutch. Country-specific regulations are automatically associated when creating quotes and orders.”

Result

There’s another area of complexity that’s crucial for the company’s growth and future that CPQ is making easier. Customers can place an order for a specific machine, but a single order can consist of 6 sub-configurations. CPQ can handle all the details and data involved – in particular all cost and time calculations for project management, resources, supplier, installation, even budget items such as travel time and expense for consulting. Budgets and costs are configured and changed in real time, working in the CPQ itself or through an online portal.

As Jansen continues to expand, the company will be poised to turn single orders into long-term customer relationships. The depth of functionality CPQ offers helps Jansen secure a worldwide base of loyal customers and save hours, even days of time creating accurate, compliant quotes and orders.

More Client Stories

Takeuchi MFG, Ltd

Compact Earthmoving Equipment Manufacturer Cuts Order Creation Time for Dealers from Hours to Minutes

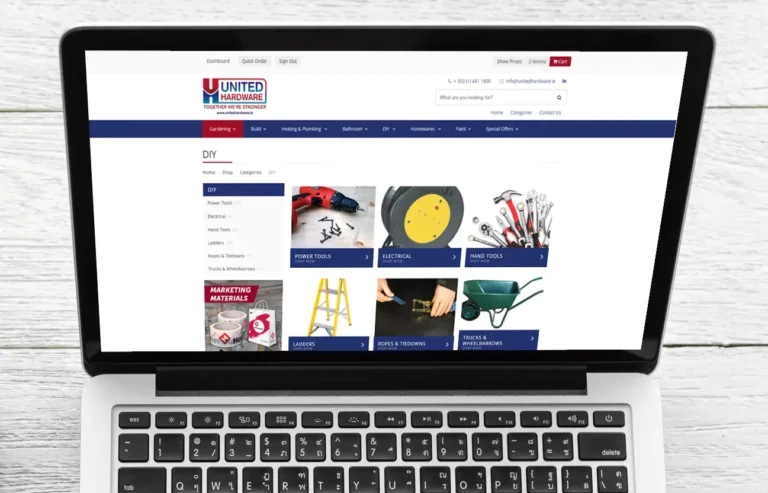

United Hardware

United Hardware simplifies product discovery and catalogue management with Experlogix Digital Commerce

No posts found